CNC Machine Shop Services

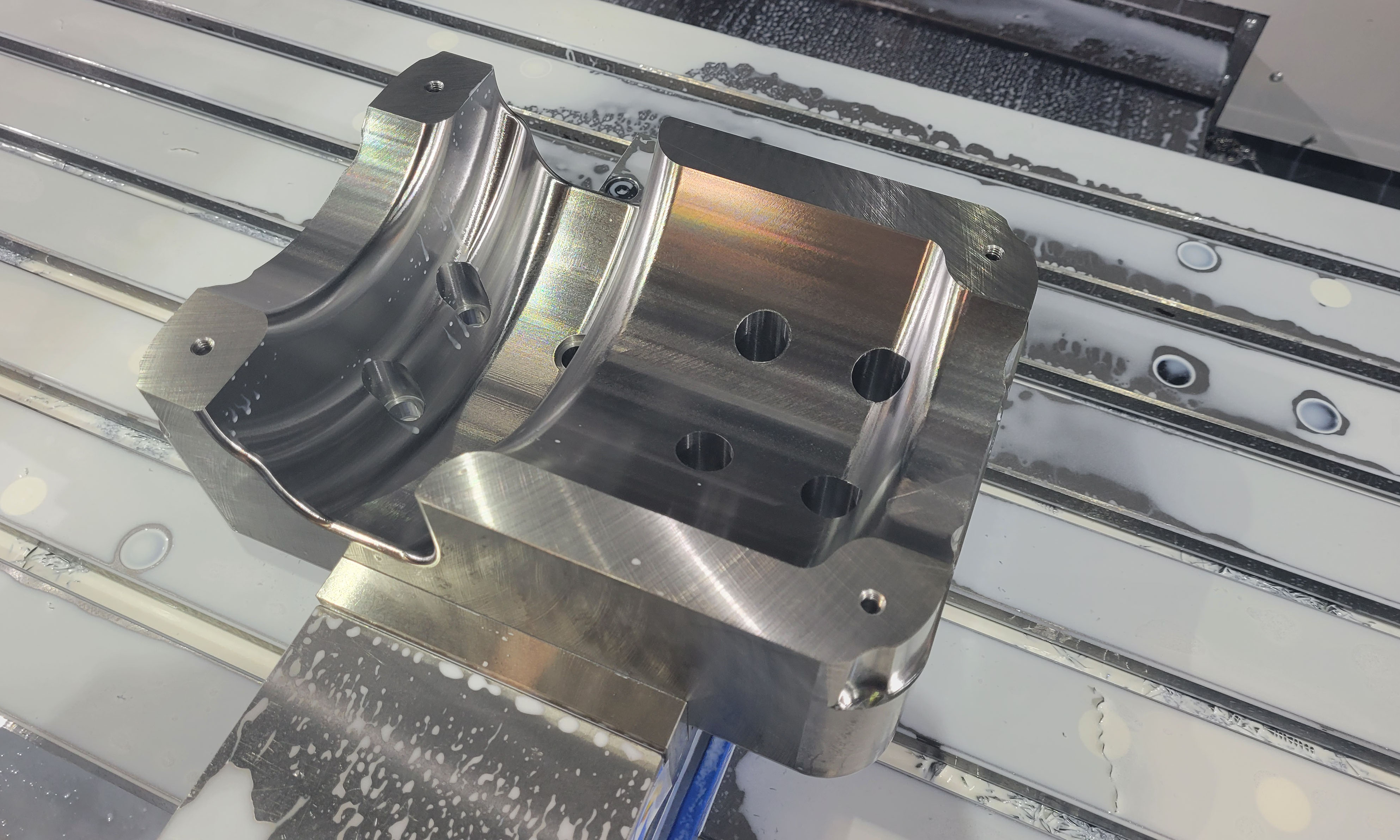

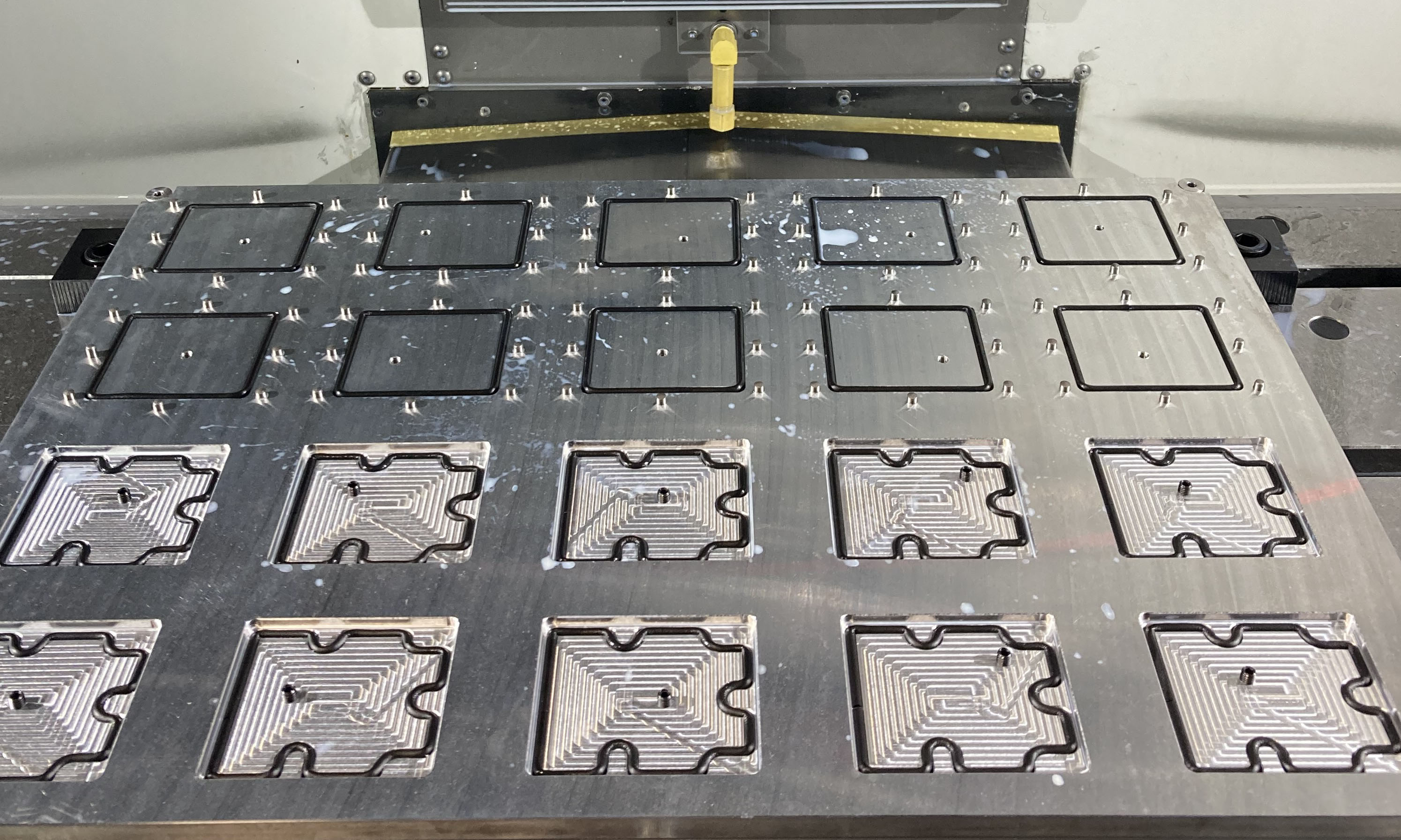

CNC Milling

FUSION 360 software | state-of-the-art with digital probing | 4th & 5th AXIS | 1 and 2 piece runs | first part inspection

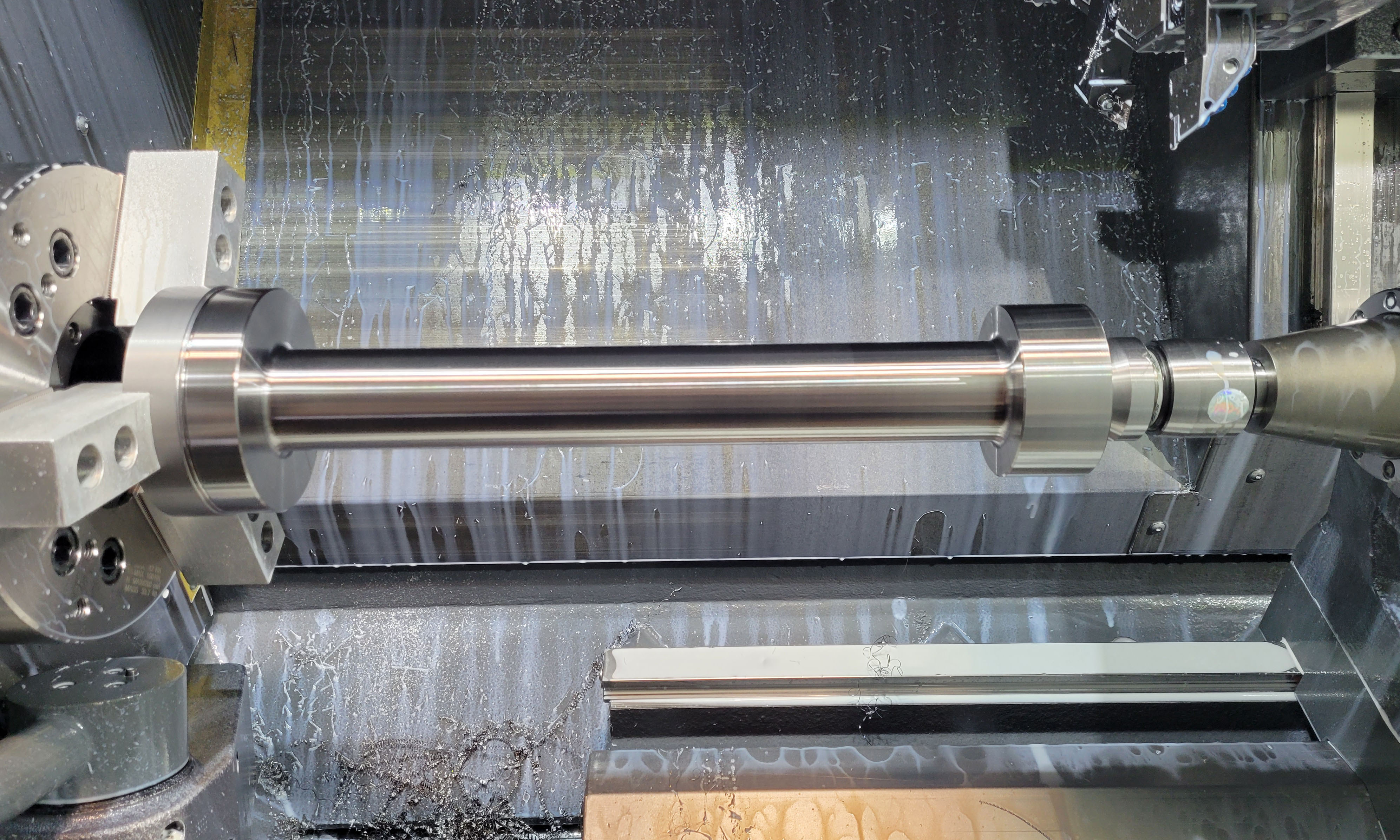

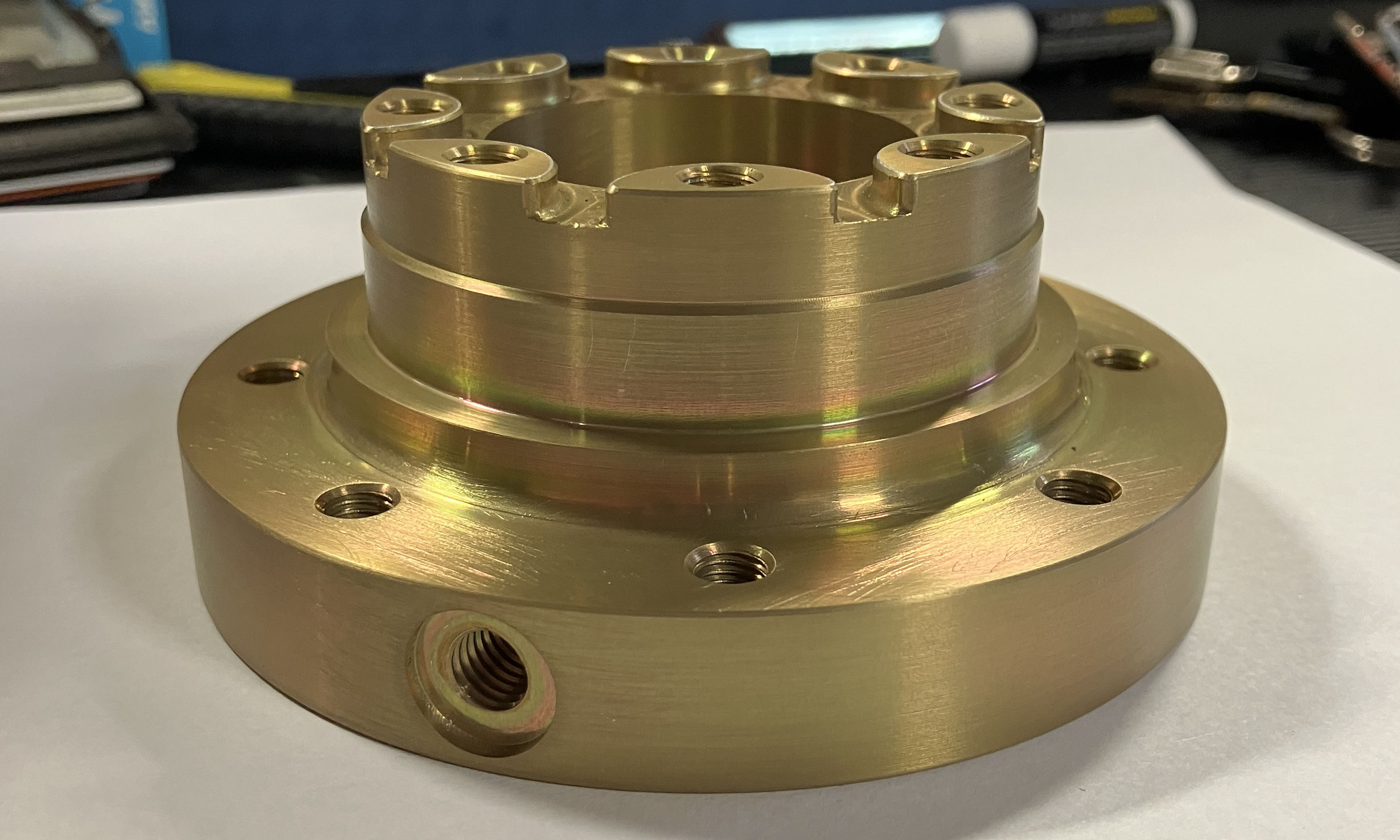

CNC Turning

SLX Prototrak lathe | internal/external threading | short run specialist | complex parts | simple parts | same day service

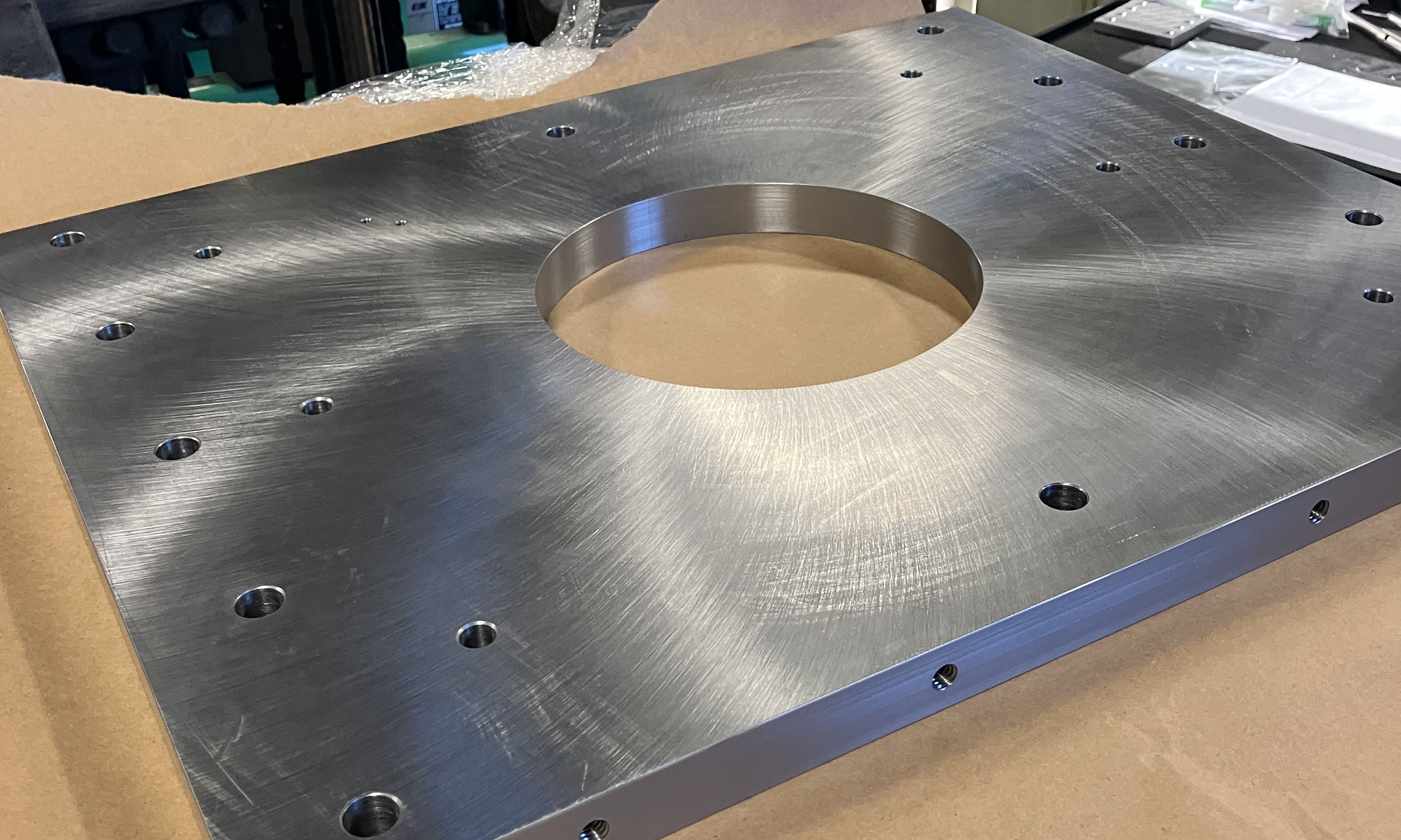

Conventional Milling

Bridgeport EZ Trak | X and Y ball screw accuracy | fast 1 piece details | simple brackets to complex machining

Precision Grinding

blanchard grinding | surface grinding | jig grinding | ID OD Grinding | centerless grinding

coatings

black oxide | zinc | clear zinc | powder coating | in house paint booth | bright zinc

Advanced diverse materials

aluminium | stainless steel | brass | plastic | certified welding | custom fabricationMakers of tools, fixtures, details and assemblies

implementing continuous improvement

Multiple Software & Capabilities

- We have upgraded all our software to Fusion 360 and do all adaptive milling on our CNC

- Fusion 360

- Auto CAD

- Solid Works

- Build only of details, fixtures, and gages

- Prototype as well as production runs

- Reverse engineering of fixtures, special machines & detail work

- We also do special fixtures and machines

Product integrity

- Specialists in packaging for finished products

- We have upgraded to standard tooling and heat shrink holders to expedite jobs quicker, a cost savings to our customers.

- Individual product identification with CNC Dot Peen machine

- Material traceability

- Certificate of compliance

- Value added service compliance and traceability

- Inspected to ensure dimensional requirements are satisfied and accurate

Inspection

- Rite Tool maintains a fulltime quality control department

- All employees are trained in our formal, ongoing quality program

- All machines and inspection equipment calibrated every 6 months to a year

- In-house inspection reports as well as customer reports are generated

- Material and heat treat certifications are available

- Processing stamp placed on each print to verify process involved

- In-house rework documented and reviewed daily

- Continuous improvement implemented at Rite Tool Inc.

On time expedited orders

- All quotes are turned in within two hours

- Material is ordered within one hour of receiving your purchase order

- Typically, material is received same day to next day of purchase order being placed

- In-house inspection reports as well as customer reports generated

- Rite Tool employs an in-house job tracking system, updated daily, with customer communication troughout the process.

- We have a near perfect, on time delivery record for all orders.

- Our customers grade us on delivery currently and we receive rating from them monthly.

Trust Rite Tool for uncompromising

precision & quality